In the aluminium industry, product quality and process efficiency are critical factors that determine competitiveness. From raw material recording, melting process control, to molten analysis, every step requires accuracy and speed. Unfortunately, many aluminium plants still rely on manual recording or disconnected systems, leading to fragmented data that is difficult to trust.

A dedicated Laboratory Information Management System (LIMS) for aluminium plants is the answer to these challenges.

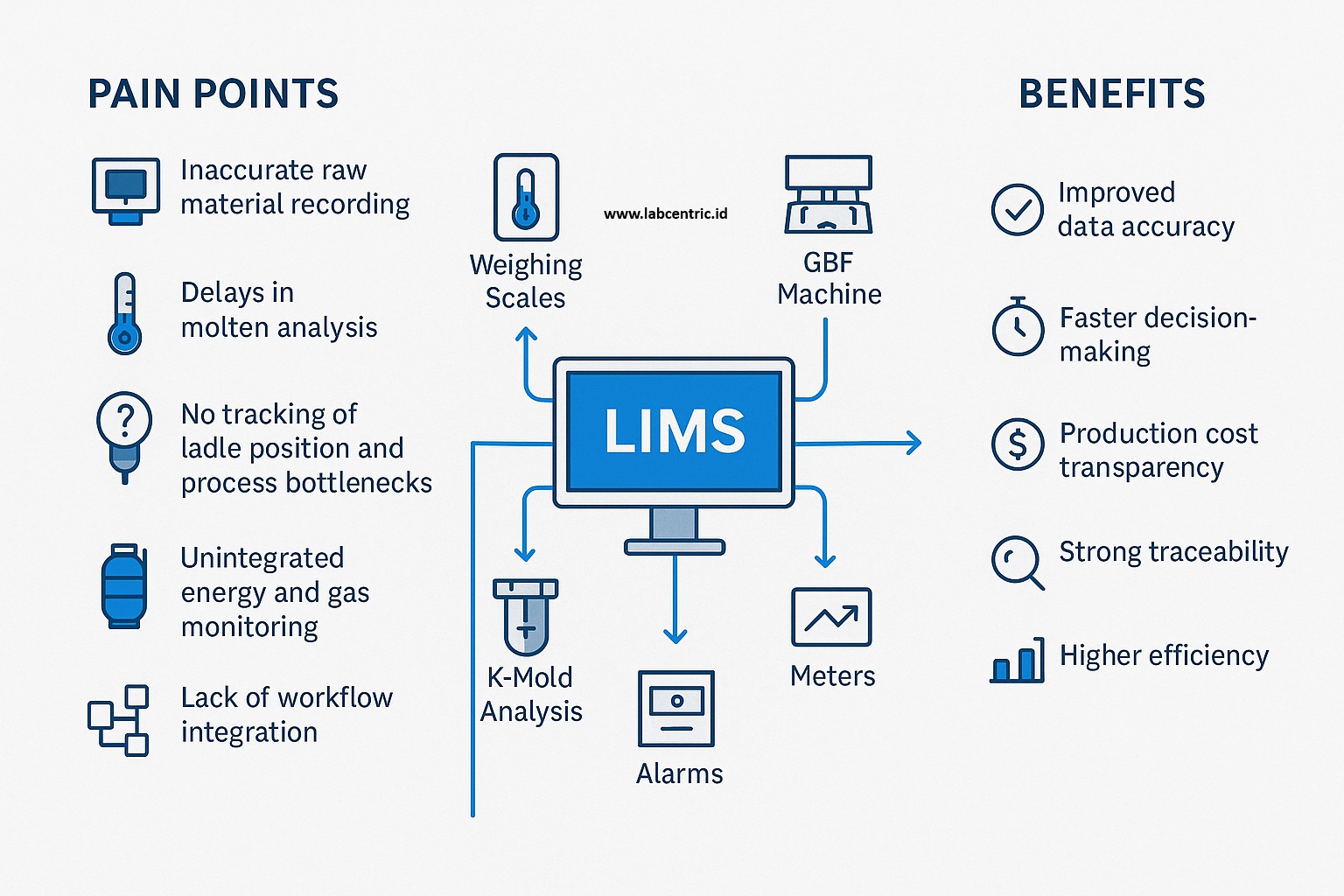

Pain Points of Aluminium Plants Without LIMS

Inaccurate raw material recording

Many plants still use manual logs for weighing raw or incoming materials. This often leads to discrepancies, difficulties in audits, and lost traceability of material origins.

Delays in molten analysis

Sample preparation, data entry, and analysis reporting are often delayed because data does not flow automatically into the system. This causes late decision-making and can even result in NG (Not Good) heats.

No tracking of ladle position and process bottlenecks

Plants often lack visibility over ladle movement, waiting times at GBF machines, or bottlenecks in the production line. Without proper tracking, it is difficult to optimize capacity and minimize downtime.

Unintegrated energy and gas monitoring

Gas, electricity, or LNG usage is often recorded separately from production data. This prevents management from calculating cost per heat or cost per ton in real time.

Lack of workflow integration

From preheating, charging, melting, holding, to delivery, data is often siloed. Without proper charge number tracking, it becomes very difficult to trace issues when rejections occur at the end of the process.

LIMS Integration with Instruments and Machines in Aluminium Plants

Modern LIMS is not just software—it serves as the central hub for data integration across laboratory and production environments. Critical integrations include:

-

Weighing Scales

Automatic logging of raw material, incoming material, and scrap inputs directly into the system. -

Thermometers (Thermocouples)

Real-time monitoring of molten aluminium temperature to ensure melting and holding stages meet specifications. -

K-Mold Analysis

Integration with K-Mold testing data for assessing molten mechanical properties. -

GBF Machines (Grain Refiner / Modifier)

Treatment process data such as dosage and timing are recorded directly in the system. -

RFID Readers for Ladle Tracking

Each ladle can be tagged with RFID to automatically log its position and transit times, helping identify bottlenecks in the production line. -

Audio & Visual Alarms

Linked to molten analysis status (OK/NG). Operators receive immediate alerts if a heat goes out of spec. -

LNG Meters, Gas Meters, Power Meters

Energy consumption is logged directly into the LIMS, enabling management to calculate energy efficiency and cost per heat or batch.

LIMS Integration with Aluminium Production Workflow

Beyond instruments, LIMS connects with workflows to create a fully digitalized production process:

-

Preheating ? Energy consumption and duration are automatically recorded.

-

Charging ? Weighing scale data automatically logs raw material and scrap inputs.

-

Melting ? Thermocouple readings and energy consumption are logged in real time.

-

Holding ? Integrated alarms ensure molten stability.

-

Treatment (GBF/Refiner) ? Parameters and process timing automatically stored in LIMS.

-

Sampling & Analysis ? Data from spectrometers and K-Mold tests are captured instantly.

-

Delivery ? Charge number tracking, ladle position, and energy usage are consolidated.

With full integration, every heat has a digital twin—a complete digital trace of input materials, process parameters, analysis results, and delivery outputs.

Key Benefits of Aluminium LIMS

-

Improved data accuracy – No more error-prone manual entry.

-

Faster decision-making – Analysis results flow instantly into the system with automated alerts.

-

Production cost transparency – Energy and material costs calculated in real time.

-

Strong traceability – Every heat has a charge number with complete history.

-

Higher efficiency – Bottlenecks can be identified and solved faster with ladle tracking data.

Conclusion

Modern aluminium plants can no longer rely on manual records or fragmented systems. With a dedicated aluminium LIMS, all data—from weighing scales, thermometers, K-Mold, GBF machines, RFID ladle tracking, to energy meters—are fully integrated in a single platform.

The results are not only more stable molten quality, but also energy efficiency, transparent production costs, and faster decision-making.

If your aluminium plant is still struggling with data management, now is the time to move to a purpose-built Aluminium LIMS.

FAQ about Aluminium LIMS

Q: Why do aluminium plants need a specialized LIMS, not a generic one?

A: Aluminium production is different from general chemical labs. Plants need direct integration with weighing scales, furnaces, K-Mold, thermometers, and energy meters. Generic LIMS only focus on lab data, while aluminium requires end-to-end workflow management.

Q: What is the benefit of integrating weighing scales with LIMS?

A: Every material receipt (raw or scrap) is automatically logged with supplier, date, and weight. This reduces errors and strengthens traceability.

Q: Can LIMS connect to production machines like GBF or ladle tracking?

A: Yes. Labcentric LIMS supports integration with production machines. GBF parameters, RFID ladle tracking, and alarms can all be recorded and analyzed in real time.

Q: How does LIMS reduce NG (Not Good) rates?

A: LIMS automatically triggers warnings when analysis parameters are out of spec. Operators are alerted immediately, preventing NG heats before they escalate.

Q: Can LIMS be used for compliance and audits?

A: Absolutely. All data is automatically archived with full audit trails, helping companies comply with ISO, IATF, and other international standards.

Q: How long does it take to implement Aluminium LIMS?

A: It depends on the scope. Basic integration (weighing scales, thermometers, OES) can take a few weeks. Full workflow integration (melting, ladle tracking, energy monitoring, delivery) may take several months in phased stages.